Testing and Development of Beneficiation Processes on a Laboratory Scale

Laboratory testing provides valuable information about the performance of the beneficiation process in case of the material being tested. The process can also be flexibly optimised and developed as necessary. GTK Mintec seamlessly combines laboratory-scale tests with process mineralogy and industrial-scale beneficiation technology research. The customer can order one study or the optimisation of the entire process.

Customised methods enable flexible research

Laboratory studies are suitable for different sample sizes

Laboratory testing of recycled materials is also possible

Laboratory studies enable flexible testing and small-scale development of production phases

Mineralogical studies and various beneficiation tests are needed during the lifecycle of a mineral deposit in connection with actions such as exploration, evaluation of the deposit, planning of a mine and concentration plant, and product quality control.

Laboratory-scale beneficiation research is also needed to assess the beneficiation and commercial exploitation potential of a wide range of secondary raw materials such as industrial slag, extractive waste and tailings.

The laboratory-scale research produces small-scale results that provide important information for the next process stages.

Versatile research methods and modern equipment

GTK Mintec’s process laboratory conducts crushing, grindability and beneficiation studies tailored to customer needs. The most commonly used beneficiation method is flotation. The laboratory also conducts studies on gravity and magnetic separation, as well as hydrometallurgical leaching studies. Cyanide and pressure leaching are typical methods in leaching studies. Process chemistry measurements such as redox, hydrophobicity and electrode potential determination are also included in the process laboratory’s service portfolio.

The laboratory-scale research phase provides a preliminary understanding of the performance and suitability of the different unit processes and their combinations for the input material to be studied. The required volume of samples is typically 30–300 kg depending on the scope of the study.

Cutting-edge innovations in the industry, digitalisation, automation and the modern equipment benefit the customer.

Flotation is the most common beneficiation method. GTK Mintec’s beneficiation laboratory has several flotation machines. An automatic foam stripper developed by GTK ensures accurate and reproducible test results.

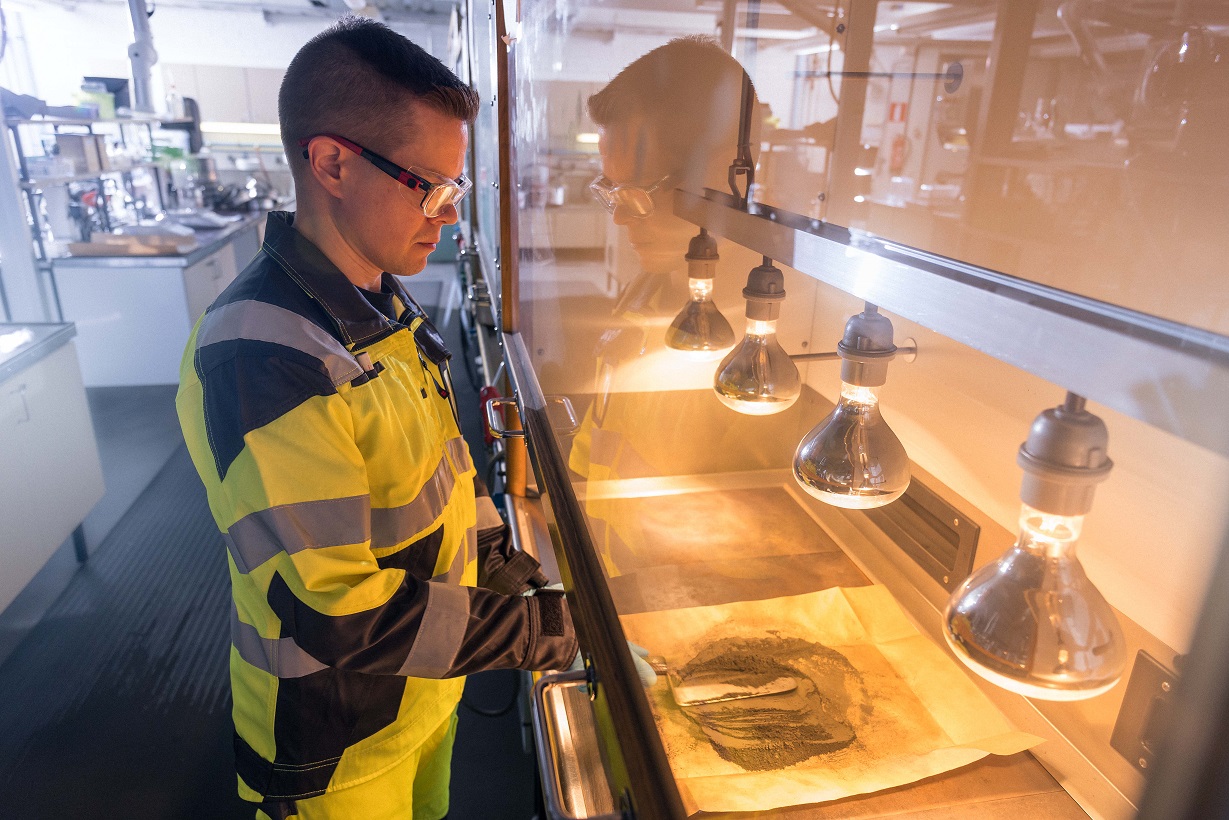

Samples from beneficiation tests carried out at the GTK Mintec beneficiation laboratory being dried using hot plates and infrared lamps.

Gravity is used to separate minerals of different weights. The image shows a Knelson gravity concentrator.

GTK Mintec – a pilot plant and laboratories for the circular economy and mineral processing

GTK Mintec is a globally unique service provider. It combines mineral research laboratories with an industrial-scale pilot plant and a testing platform for the long-term behaviour of extractive waste.

Contact us

Leave your contact information and we will get back to you.