Process Mineralogy Research

Mineralogy studies assist in the design and optimisation of the beneficiation process, as well as provide essential information about the utilisation of ores and industrial by-products, for example. In GTK Mintec, process mineralogy research is seamlessly combined with laboratory-scale testing and industrial-scale beneficiation technology research.

Background information for planning the beneficiation process and further processing

Risk assessment and information about long-term behaviour

Research service package enables innovative solutions

The process mineralogy laboratory studies primary and secondary materials in a versatile manner. Process mineralogy studies identify minerals or phases present in an ore sample, an industrial by-product or another material being tested.

The study provides information on the material’s raw material potential, valuable material concentrations and potential applications as new products. In addition to these, GTK studies the concentrations of detrimental materials and any other risk factors related to long-term behaviour such as the structure and phase composition of the material. This information helps in the design and optimisation of the beneficiation process and further processing.

Mineralogy research is carried out based on the customer’s research problem and samples. Samples typically include ores, concentrates, tailings, slags from the metal industry and ash from energy production.

The following are studied:

- Minerals or phases present

- Quantity of minerals or phases

- Degree of liberation of valuable minerals

- Grain size distribution

- Presence of valuable minerals among other minerals

- Presence of detrimental minerals can also be investigated

As part of its service offering, GTK continuously develops its mineralogy research methods and utilises cutting-edge technology in its research.

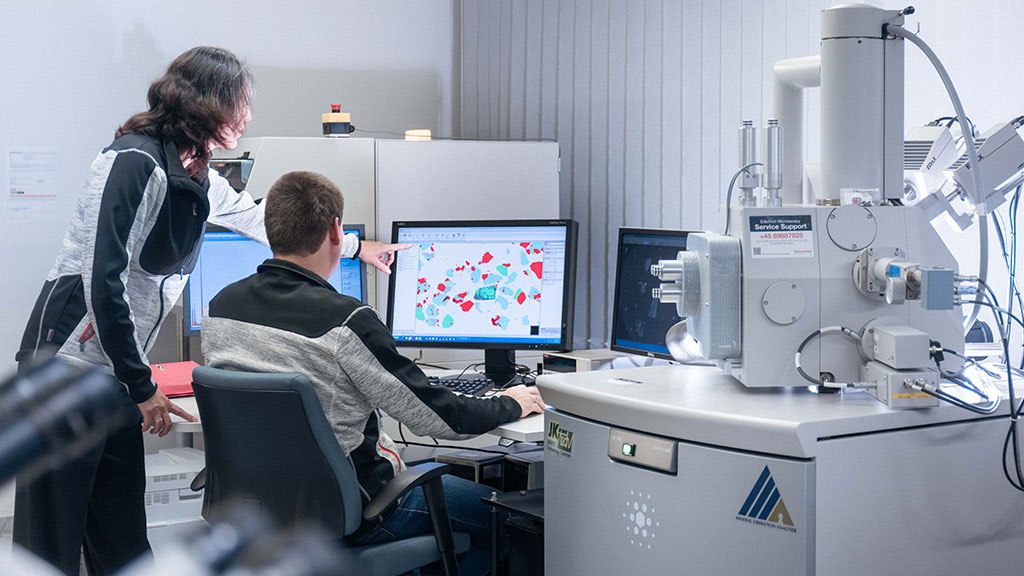

The process mineralogy laboratory has instruments such as a field emission scanning electron microscope (FE-SEM) with different MLA, Qemscan and Amics software for automated mineralogical research.

X-ray diffraction analysis or XRD is one way to analyse a sample. It is used specifically for Rietveld analysis.

GTK Mintec – a pilot plant and laboratories for the circular economy and mineral processing

GTK Mintec is a globally unique service provider. It combines mineral research laboratories with an industrial-scale pilot plant and a testing platform for the long-term behaviour of extractive waste.

Contact us

Leave your contact information and we will get back to you.