It’s Time to Wake Up - There Are Bottlenecks in Raw Materials Supply Chain

The research report made by Associate Research Professor Simon Michaux from Geological Survey of Finland GTK (published August 20, 2021) shows that if we want to transition away from fossil fuels, mining of minerals and using recycled minerals and metals from industrial waste streams in new ways will have to increase greatly. The refining of observations into scientific publications is continuing.

A Glimpse of the Systemic Overview Is Here, Discussion and the Development of the Solutions Have Started

The research report brings up preliminary calculations and systemic interdependencies of this broad entity. Now there are 3 videos available where

- Simon P. Michaux explains the key points of the report,

- he answers to the hot topics around the matter and

- he discusses the matter with Peter Handley (European Commission), Jukka Leskelä (Finnish Energy), and Saku Vuori (GTK).

The World needs a new plan to build a genuinely sustainable non-fossil fuel industrial ecosystem

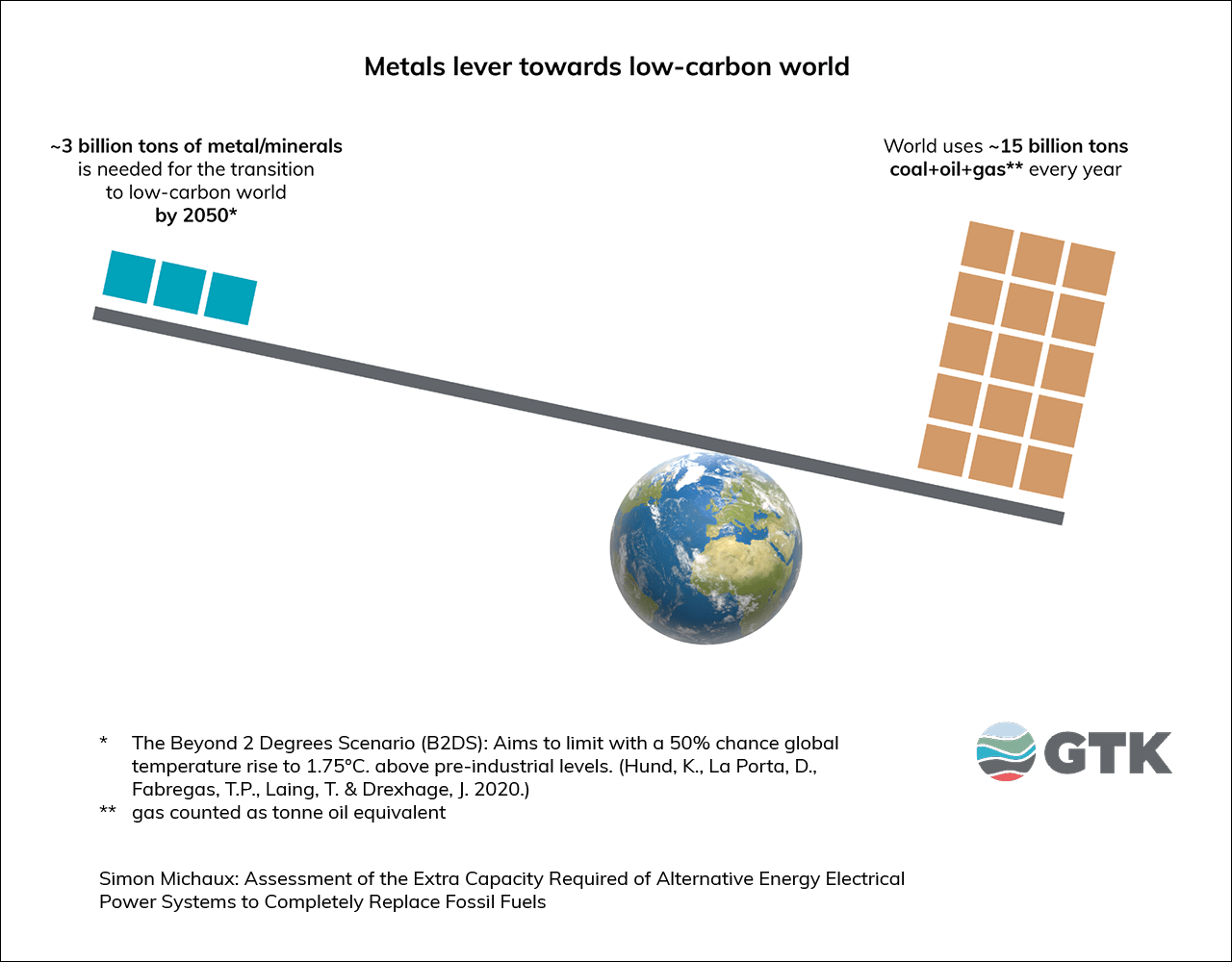

No matter what minerals will be needed, we will need large quantities of them as the renewable power sources like wind and solar, require extensive mineral resources to manufacture the infrastructure for fossil-free energy.

And there is a challenge. Preliminary calculations, presented in the research report, includes number of vehicles in different vehicle class in year 2018 and what does it take to transfer that mass to Electric Vehicles (EV’s). Based on this number, it is clear that there are not enough minerals in the currently reported global reserves to build 1,4 billion EV’s in the global industrial ecosystem as it is today. This calculation is showing the scale of the task, not predicting the future. There are wide variety of estimates on the number of vehicles we will need in the future, as well as the rate of change for the vehicle fleet composition. Battery recycling has the potential to ease the transition during the next 10-15 years, but is not a solution on its own.

Decisive actions need to be planned to diversify sustainable material/metal/mineral sourcing, where manufacture could be done with parallel technology systems that require different material chemistries. In doing so, current reported mineral reserves may be sufficient for long term supply.

Key elements include developing new ways to utilize minerals, metals and materials of our industrial waste and to promote manufacture of easily recyclable products.

Exploration for new mineral deposits, feasibility studies, and pilot scale tests of existing known deposits will be needed on an unprecedented scale, will be needed all over the world. The restructuring society and the industrial ecosystem to consume less and establish a new relationship with raw materials and energy might be needed.

We need to change how we direct the use of materials to essential uses such as the construction of a new energy system instead of consumables.

We also need to re-evaluate our current thinking. Is it sustainable to focus exclusively on lithium-ion battery chemistry? Are there alternatives (like fluoride or sodium-based chemistries)? How do we ensure materials supply to facilitate the development of the energy transition most sustainably in a systemic level, at a global scale? How could this be done with the assistance of primary and secondary metals extraction?

Many systems and products that we currently take for granted may soon become impractical at current levels of consumption. For example, is it possible to invent solutions to change large-scale agriculture from its dependency on petrochemical fertilizers, pesticides, and herbicides, or is there a role for small scale organic farming methods to produce the needed food products? Can the plastics industry be resourced with bioplastics, and if so, how much biomass can be harvested sustainably? If oil is to be no longer used to produce rubber, how will we manufacture car tires?

It’s time to start the discussion

Parallel but complimentary solutions are needed to be implemented. Finland has the key industrial assets to develop a fully vertically integrated non-fossil fuel industrial ecosystem. Finland also has the capacity to mine minerals, refine them, produce chemicals, and smelt metals. If this was organized appropriately, Finland could develop an integrated ecosystem representing one entire end of the value chain, from minerals to refined chemical products. So, despite all the significant challenges, there is a huge opportunity to secure Finland’s economic future. Finland’s net position to transition away from fossil fuels is much stronger than many other nation states.