Service package with a ground-penetrating radar and a drone for peat research

There has been a long-term customer relationship between the Geological Survey of Finland (GTK) and Vapo Group in the study of peat production fields. During the last 20 years, over 400 peat production areas have been surveyed with ground penetrating radar (GPR) using a line spacing of 40 metres. The total area surveyed has been approximately 45,000 hectares. This equates to approximately 10,000 kilometres of GPR survey line and approximately 3.9 million drill points equivalent to radar interpretation points.

GTK’s current GPR equipment comprises an SIR 4000 control unit with 100 MHz, 200 MHz and 250 MHz GSSI antennas, a Trimble VRS-GPS system (R10/T10) and a Polaris 900 RZR utility vehicle with accessories (Image 1). The data from peat production areas needs to be updated several times throughout their life cycle, and so areas have been surveyed again to update the data.

The research data are utilized in refurbishment plans for production fields, applications for environmental permits, mass calculations and the preparation of production plans. Current energy policy-related discussions have called for reducing or stopping the use of peat in the production of district heating and energy. However, peat will most likely be used until a replacement raw material is found and the suitable boiler technology has been upgraded in existing power plants.

In peat production areas, the contractors can produce peat so that the surface of the peat layer lowers by a maximum of 15 cm each year, although the amount in each section varies depending, among factors, on the section’s drainage conditions. Due to this, the surface of the field does not decline uniformly throughout the production area.

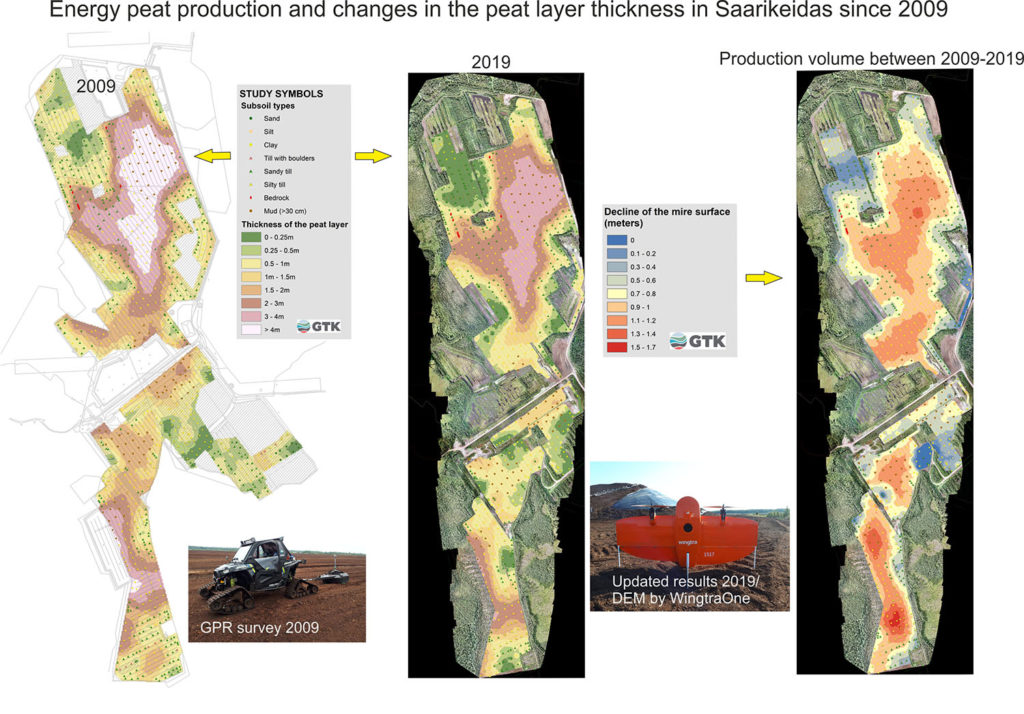

The surface level of the production field and its possible decline are key parameters when there is a need to update research data. The topography of the bottom, the possible gyttja layers and information on the subsoil type remain unchanged. These aspects do not need to be surveyed with GPR again if the elevation level of the production area can be accurately determined.

With modern photogrammetry-based imaging technology installed on a drone, it is possible to form an accurate 3D point cloud, an orthophotomosaic and a digital elevation model of the terrain. The current surface level of the production area can be determined from the digital elevation model with an accuracy of a few centimetres. As we already know the topography of the peatland’s floor from earlier surveys, it is easy and cost-efficient to update the data to correspond with the current situation. After updating the data, the remaining amount of peat and the efficiency of peat production in the whole production area and its different sections can be determined (Image 2). The basis for everything in the method is the interpretations made from previous GPR surveys, and GTK’s archive holds GPR interpretation data on 10,000 kilometres of peatland. Without the existing GPR surveys, a measured surface model would have no value.

Throughout the years, the coded interpretations of GPR survey data (linked to the customer’s databases and seen in printed maps) have been classified and presented in as uniform and standardised a manner as possible. This ensures that designers in offices and contractors out in the field can immediately gain an overview of the production area’s situation from the database and different printouts.

Updating of GPR data starts with the conversion of the combined interpretation packet’s height and coordinate system to the newer systems currently in use. After this, the interpretations are integrated into the new elevation model, and the thickness of the remaining peat layer and the decline in the surface level in different sections of the production area are calculated and updated.

Interpretation points transferred to the new model must then be inspected to check/verify their location. For example, interpretation points located on dredged material from ditching, on filled production strips or on peat extraction stocks give negative values for the decline, as the surface level falsely appears to have risen in comparison to the values from the previous survey. Interpretation points on forested areas that have been abandoned and points in the collected peat ridge in the middle of the strips must be deleted, because at these points, the elevation model does not represent the current ground level. In addition to the thickness of the peat layer and the decline in the surface level, an up-to-date slope map for the production area is also produced.

In the summer of 2018, testing began to assess whether GPR survey data could be updated with photogrammetry. Immediately after the firsts test, it was concluded that the collection of flight data with geocoded ground control points from a peat production area of several hundred hectares was very time consuming. A relatively new technique called post-processing kinematic (PPK) turned out to be the solution to this problem. The technique enables the accurate geotagging of images without the need for ground control points. Rinex post-processing files from data produced by the surveyor’s own base station can be incorporated into the PPK. Optionally, the post-processing data produced by Geotrim’s VRS counting station can be used. The service provided by Geotrim is a practical solution for this, and it is also used by GTK.

In the autumn of 2018, a GeoDrone PPK X4L multirotor was leased and used to survey 1,600 hectares of peat production areas. The drone worked reasonably well in principle, but its performance was lacking. Performance refers here to the flight time and flight speed. The GeoDrone could cover an area of 30–40 hectares at a speed of 6 m/s, so covering a 400-hectare area required ten separate flights. This brought added costs for operations in the field, as well as in the office. The solution for the performance issue came in the form of the relatively new VTOL-PPK drones.

After some market research and comparisons were conducted, the Swiss WingtraOne VTOL drone was chosen. VTOL drones take-off and land vertically, and can thus be operated within a small area. A so-called transition height is defined for the device, where the device changes the vertical ascent to a horizontal position and is circumferentially directed to the altitude specified in the flight plan. The WingtraOne has an operational cruise speed of 16 m/s, which means it can survey almost 100 hectares in around 25 minutes. The flight plan is prepared on-site with WintraPilot software.

The maximum flight altitude allowed for drones in Finland is 150 metres, which means that a SonyRX1RXII 42 MP camera with 70% overlap in length and width provides images with a pixel size of 1.9 centimetres. At the office, each pixel is used in the vector analysis of five different pictures, which means that a computer with a high processing capacity is required to produce an elevation model with Pix4D software. These calculations are conducted by Mika Larronmaa using the equipment of GTK’s Corporate Geodata Management unit.

Finnish legislation requires that the person controlling a drone ensures the visibility of the drone. The factory setting for the geofence of this 125-cm-wingspan device is 1,200 metres. The quality of the produced elevation model has been monitored with reference points measured for each flight area with a high-precision GPS device. The differences between the produced elevation model and the 70 values of the control points have been from 3–6 centimetres on average. The largest difference was 12 centimetres, which was caused by poor satellite geometry. The results are excellent considering that around 50 flights were conducted in the summer of 2019 with the WingtraOne and the drone travelled over 1,000 kilometres in the air.

GPR surveying and updating GPR interpretations with a drone is a very effective combination for peat research. In addition to being accurate and cost-efficient, the two parts of this method support each other’s seasonal nature. During the most active production season in the summer, it is often impossible to go out into the fields with a utility vehicle due to the high risk of wildfire. However, summer is an excellent season for performing drone surveys. During rainy autumns and in winter, drone operations are impossible, but conditions are optimal for conducting GPR surveys, since the terrain is dust-free and less prone to catching fire.

WingtraOne’s upcoming upgrading surveys of peat production fields will reduce the length of GPR exploration by about 1,000 kilometres. This will mean significant workload savings and reduced measurement costs for the customer.

Even though the WingtraOne was primarily selected based on its ability to perform photogrammetrical surveying over large areas, as well as the high quality of its components and software, the drone can also be readily recommended for small-scale geological surveying. For example, the WingtraOne was recently used to conduct measurements on a dimension stone quarry and its tailings stocks. This dataset was then used in the production monitoring required for environmental permits. Should the need arise, the WingtraOne can also be equipped with a Micasence RedEgge-MX multispectral camera for environmental surveying, for example.

To conclude, I’ll leave you with a slightly shaky video, shot with a phone while working. Link to the video

Best but dusty peat regards,

Heikki Sutinen

Text: Heikkki Sutinen

Heikki Sutinen is a geologist at the Geological Survey of Finland (GTK). Since 1997, he has specialized in ground penetrating radar (GPR) applications. He has conducted GPR surveys for sedimentological and groundwater purposes in esker environments, dimension stone fracturing surveys in quarries and environmental surveys in industrial surroundings. His work has also included GPR surveys to locate underground utilities, lake sediment mapping and archaeological site surveys. Nowadays, his time is mainly focused on energy peat production surveys.