Science Blog: Quality Assessment of Fine Flake Graphite in the Raisjoki Volcanic Sequences, Western Finland

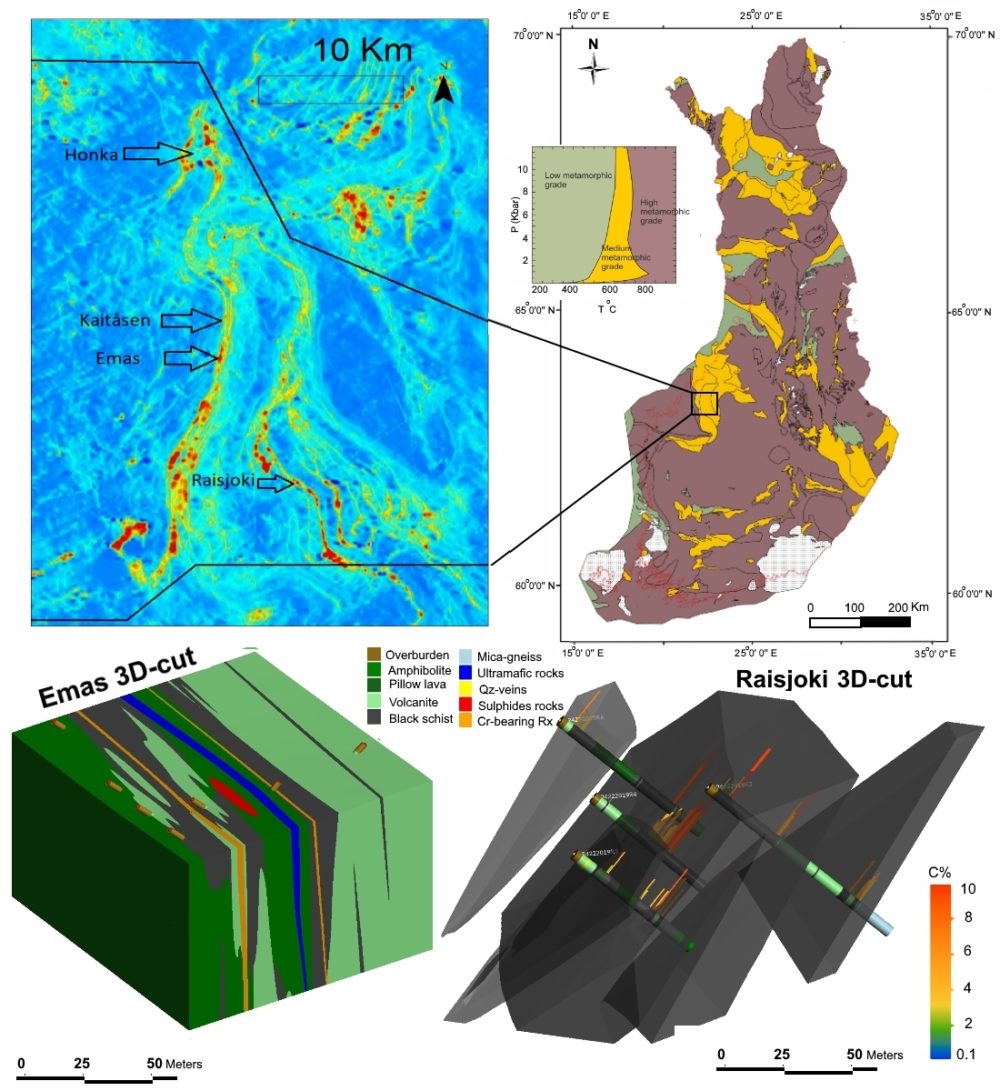

The Raisjoki project was established by GTK (2019) to assess the mineral resource potential for battery minerals, focused on graphite, Ni–Co sulphides and lithium. The Raisjoki target is located entirely within the easternmost part of the Paleoproterozoic Svecofennian schist belt, which is bounded to the west by the Vaasa complex (VC) and to the east by the Hallapuro formation mafic volcanic rocks and the CFGC granitoids (Fig. 1) (Nironen et al. 2002, Nironen 2017, Lahtinen et al. 2017). Raisjoki and Emas indicate that graphite-rich black schist layers extend for tens kilometres towards the N–S trending (Kuusela 2010, 2020, Ahtola et al. 2015). The Raisjoki project includes several exploration targets: Raisjoki (Ni–Co, graphite), Emas (graphite, Ni–Co–Au), Kaitåsen (graphite, Ni–Co) and Honka (Li–Ni–Co) (Fig. 1). These targets also belong to the N–S-trending mafic to ultramafic volcanic sequences associated with metasedimentary metavolcanic rocks, which hosted several important features, including graphite and Ni–Co–Zn mineralization (Fig. 1). Here, we focus on the mineralogical characterization of graphite in Raisjoki and we also describe the separation and purification techniques for producing high-quality graphite. The mineralogical characterization and textural relations of the minerals in Raisjoki were carried out on both graphite-bearing rock samples and final graphite concentrates.

Geology of the host rocks

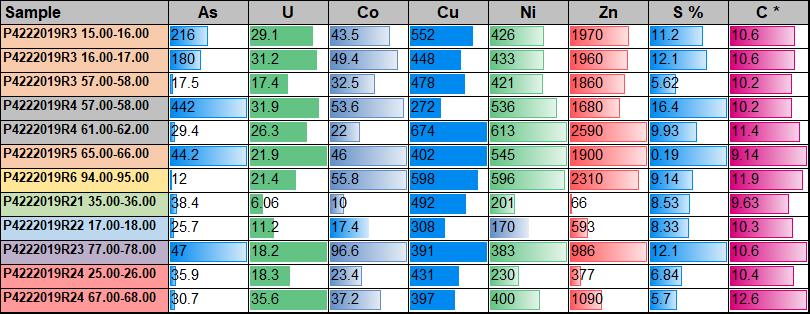

Most areas of the Raisjoki targets were metamorphosed in low- to medium-grade metamorphism, which included graphite-bearing black schists and low- to mid-amphibolite facies (Hölttä & Heilimo, 2007). Graphite mineralisation in the Raisjoki area is hosted by sulphur-bearing graphite black schists and amphibolite, and less commonly by metavolcanic interlayers. The number of graphite-bearing zones and their strike lengths were estimated using the available geophysical and geological information from each locality. The thicknesses of the units were estimated from geophysical data and drilling. 3D geological models of Raisjoki and Emas indicate that graphite-rich black schist layers extend for tens kilometres towards the NW–SE, with thicknesses ranging from a few meters up to 40 meters (Fig. 1). Raisjoki graphite mainly occurs in low to medium metamorphic grade black schist and amphibolite facies, and the graphite content in Raisjoki ranges from 5% to 12.6% (avg. 8.5% C), while the total sulphur content ranges from 2.9% to 12.3% (avg. 7.2% S). The main gangue minerals are quartz, plagioclase, sulphides (pyrrhotite, pyrite), biotite and chlorite. Table 1 summarizes the content of total carbon (TC %) and associated metals in some selected drill core samples.

Methods

- Ground geophysical follow-up: magnetic, frequency-domain electromagnetic and radiometric measurements of the sulphide and graphite mineralised areas.

- Diamond drilling of the most prospective areas and anomalies found during the exploration work, involving diamond-drilling, and representative sampling of graphite-bearing rocks.

- Beneficiation studies were performed to produce high-purity graphite concentrate (flotation separation & purification techniques).

Table 1. Several graphite-bearing samples were analysed for bulk chemistry.

Graphite petrology and mineralogy

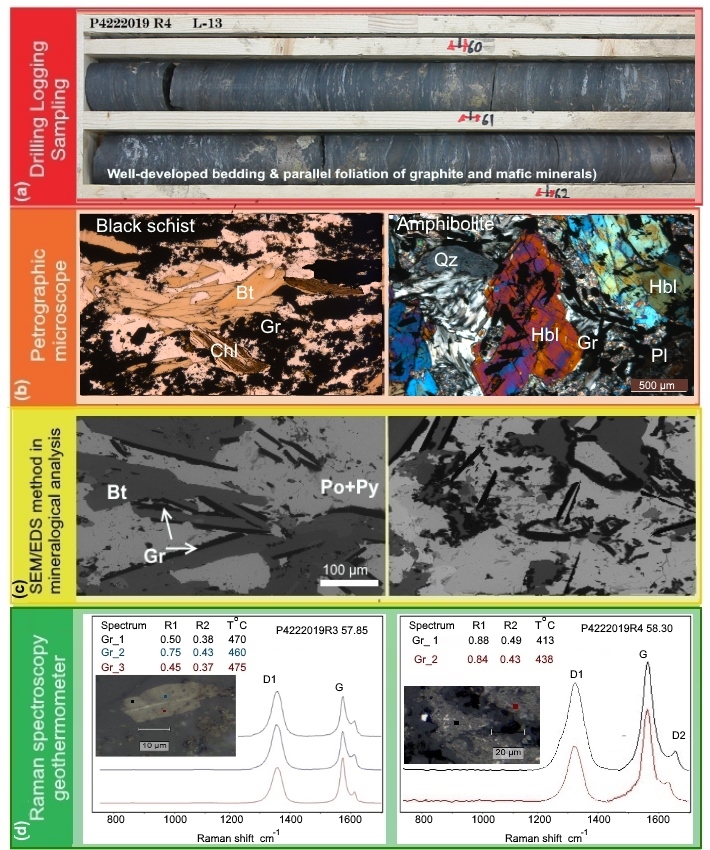

Petrographic analysis under an optical microscope indicated that graphite-bearing samples primarily consist of quartz, alkaline feldspar and biotite, with subordinate graphite, pyrite, carbonate and chlorite (Fig. 2b). Most of the graphite flakes occur as small, flat, plate-like crystals (30 to 150 μm), as fracture filling or concentrated along the mineral boundaries. In some samples, the graphitic schists can be rich in pyrrhotite, which is relatively easily deformed. This schist texture shows crystals of graphite “float” in a matrix of pyrrhotite (Fig. 2c). (Al-Ani et al. 2020, Kuusela et al. 2020).

Raman spectrometry is a rapid and simple technique to assess the graphitization temperature and degree of crystallinity of carbonaceous material (CM). Raman spectroscopy demonstrates that the flaky graphite morphologies have very similar spectra and most of graphite particles have low crystallinity that results in lower temperatures. The Raman spectrum of CM can therefore be used as a geothermometer indicating the maximum temperature reached during regional and contact metamorphism (Beyssac et al. 2002). Estimated temperatures of graphite mineralisation indicate that the flaky graphite in Raisjoki and Emas formed between 495 ± 15 °C and 430 ± 20 °C, which reflects graphite formation through progressive transformation of organic matter during diagenesis in medium to low-grade metamorphic rocks (Fig. 2d).

Graphite quality and beneficiation tests

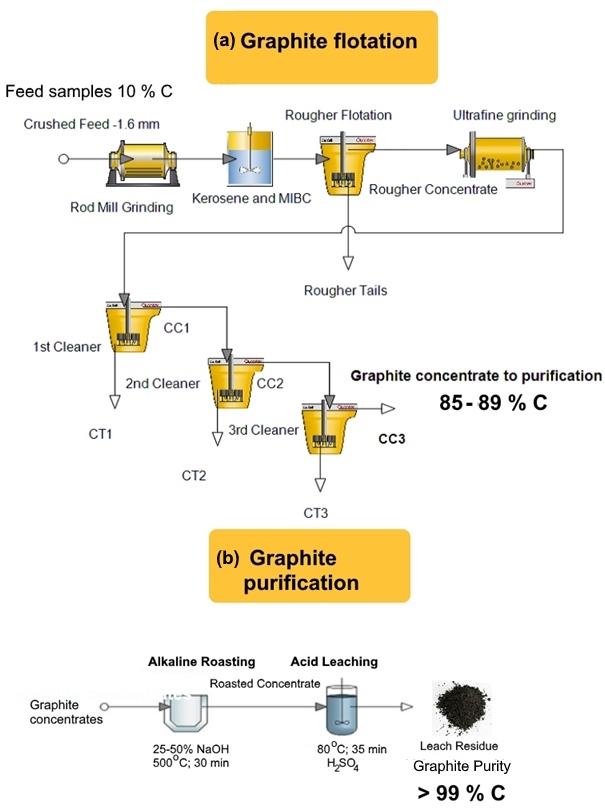

Generally, naturally occurring graphite is of low grade and as such it is not suitable for industrial applications. Froth floatation is the most used beneficiation technique for low-grade graphite. The carbon content in flotation feed samples was 10.1% for Raisjoki graphite and 7.8% for Emas graphite. Flotation experiments were performed by GTK Mintec at the bench scale, including crushing, grinding and flotation processes (Fig. 3).

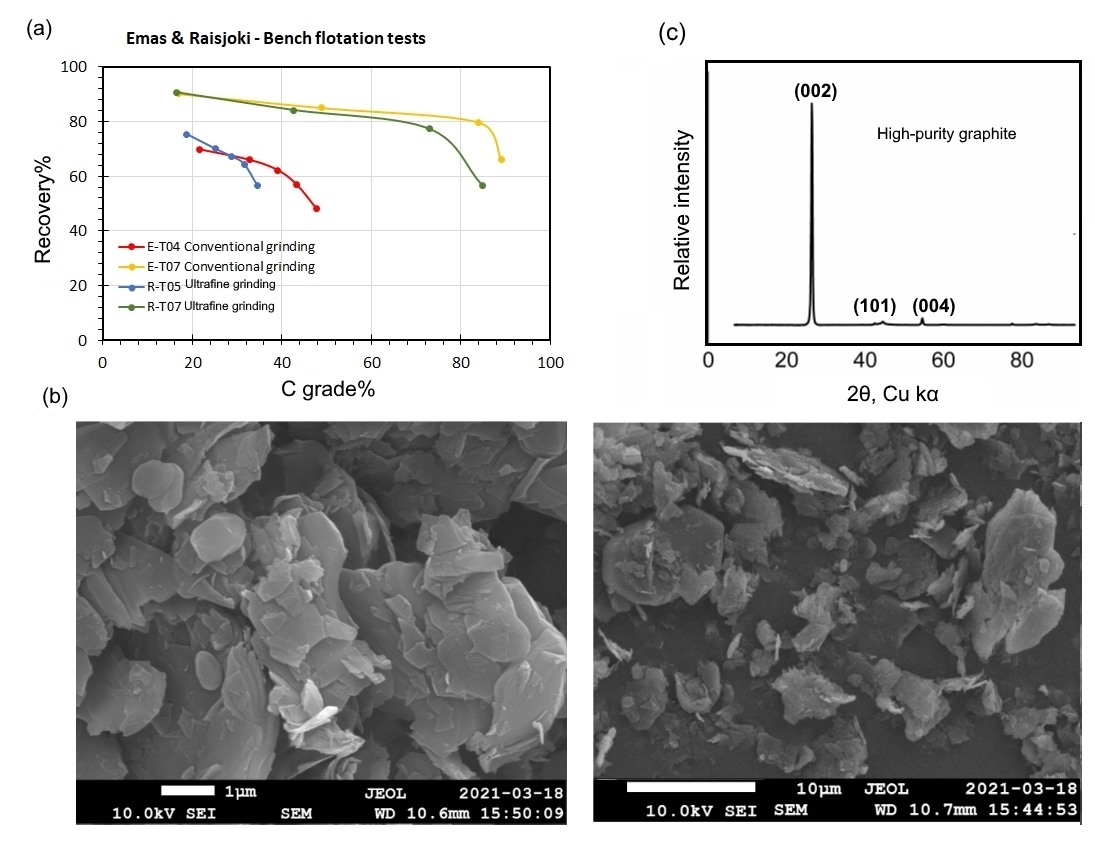

After the first grinding and rougher flotation, the graphite rougher concentrate goes through an ultrafine grinding stage for final liberation of the graphite minerals (Fig. 3a). The ground concentrate is then submitted to three cleaning steps. The carbon grade (C) and recovery achieved for Raisjoki and Emas samples, respectively, were 84.8% C at 56.9% recovery and 89.0% C at 66.2% recovery. The tests results using conventional and ultrafine grinding are summarized in Fig 4a.

Alkaline roasting and sulphuric acid leaching was used to eliminate impurities in the graphite concentrate. A flotation fine concentrate containing 85–89% carbon could be further purified to over 99% C following the alkaline-roasting process with NaOH and leaching with H2SO4 solution (Fig. 3b).

The morphologies of the ultrafine graphite (nano-sized graphite) were investigated using scanning electron microscopy (FE-SEM-EDS JEOL JSM 7100F Schottky) and X-ray powder diffraction (XRD) at the GTK Research Laboratory in Espoo. Exfoliation and separation of high purity graphite flakes is presented in Figure 4b. The images reveal that thick flakes were decomposed into many thin lamellae and there was a reduction in size of the graphite flakes to nano-micro graphite flakes with a thickness close to 100 nm and a width of <5–20 μm. XRD results appear to correspond well with SEM micrographs, indicating graphite (pure carbon) with a highly organized crystal structure (Fig. 4c). Further research should be conducted to purify fine graphite from Raisjoki and Emas to obtain the high-grade graphite required for producing of lithium-ion batteries.

Keywords: Raisjoki; Fine flake graphite; Low- to medium-grade metamorphism, High-purity graphite up to 99% C, Lithium-ion battery

References

Al-Ani, T. & Kuusela, J. & Nygård, H. 2020. Mineralogical Characterisation of Graphite Deposits in the Raisjoki area, Western Finland. GTK Open File Work Report 55/2020. Available at: https://tupa.gtk.fi/raportti/arkisto/55_2020.pdf

Beyssac, O., Goffé, B., Chopin, C. & Rouzaud, J. N. 2002. Raman spectrum of carbonaceous material in metasediments: a new geothermometer. Journal of Metamorphic Geology 20, 859-871.

Hölttä, P. & Heilimo, E. 2017. Metamorphic map of Finland. In: Nironen, M. (ed.) Bedrock of Finland at the scale 1:1 000 000 – Major stratigraphic units, metamorphism and tectonic evolution.Geological Survey of Finland, Special Paper 60, 77-128. Available at: http://tupa.gtk.fi/julkaisu/specialpaper/sp_060_pages_077_128.pdf

Kuusela, J., Nygård, H., Leväniemi, H. & Al-Ani, T. 2020. The investigations of the Raisjoki metavolcanic rocks in Evijärvi, Western Finland. GTK Open File Work Report 57/2020. Available at: https://tupa.gtk.fi/raportti/arkisto/57_2020.pdf

Lahtinen, R., Huhma, H., Sipilä, P. & Vaarma, M. 2017. Geochemistry, U-Pb geochronology and Sm-Nd data from the Paleoproterozoic Western Finland supersuite – A key component in the coupled Bothnian oroclines, Precambrian Research 299, 264-28. DOI: 10.1016/j.precamres.2017.07.025

Nironen, M. 2017. Guide to the geological map of Finland – Bedrock 1:1 000 000. In: Nironen, M. (ed.) Bedrock of Finland at the scale 1:1 000 000 – Major stratigraphic units, metamorphism and tectonic evolution. Geological Survey of Finland, Special Paper 60, 41-76. Available at: http://tupa.gtk.fi/julkaisu/specialpaper/sp_060_pages_041_076.pdf

Nironen, M., Lahtinen, R. & Koistinen, T. 2002. Suomen geologiset aluenimet – yhtenäisempään nimikäytäntöön! Summary: Subdivision of Finnish bedrock – An attempt to harmonize terminology. Geologi, 54(1), 8-14.

Text: Thair Al-Ani, Janne Kuusela, Henrik Nygård and Dandara Salvador

Thair Al-Ani has worked as a senior scientist (Ph.D.) at the Geological Survey of Finland (GTK) since September 2003. Currently, he is engaged in many projects focusing on GTK strategies relating to graphite, lithium and cobalt as raw materials in lithium-ion battery technologies and other applications for renewable energy.

Janne Kuusela is a senior exploration geologist (M.Sc.) with experience in major gold exploration projects in Finland and Sweden. Since starting at the Geological Survey of Finland in 2009, his main focus has been on evaluating the battery mineral potential for the main commodities (Li, Co, Ni, graphite) in Finland.

Henrik Nygård (M.Sc. and B.Eng.) has worked at GTK since Jan 2019. He is involved in projects evaluating the battery mineral potential in Finland (Li, Co, Ni, graphite). Previously, he has worked in Finland and Sweden for several exploration companies focusing on orogenic gold, porphyry/IOCG copper, VMS and Ni/Zn targets.

Dandara Salvador (M.Sc. Eng. and Geol.) is a research scientist in the mineral technology field, with expertise in battery and high-tech minerals and metals, such as Li, graphite, REE, Nb and Ta. Her work at GTK includes ore characterization and testing of mineral processing, both at bench and pilot scales, for feasibility studies, research projects and operating mines.