Raw Materials and Security of Supply – It Is Time to Act, Now

“The raw material requirements of the green transition look extremely demanding for cobalt, nickel, lithium, vanadium, rare earth elements (REE) and many other metals when we compare the predicted demand with the current production and mine reserves,” write Janne Hokka and Pasi Eilu from the Geological Survey of Finland.

Manufacturing a mobile phone requires 60–70 different metals and minerals. The same phenomenon can be seen in all industrial production: more and more commodities mined from the ground are used for a single product. Globally, we also see an increase in the use of all raw materials, whether it is sand and steel or copper and platinum, as citizens’ standard of living rises.

The green energy transition is predicted to require a very strong growth in mining worldwide, dominantly targetting at specific valuable metals. There is also no indication that either the use of any metal or mineral for other purposes is decreasing – on the contrary.

The growing demand for minerals inevitably raises questions about their sufficiency. Increasing recycling is calculated to cover only 5–20 percent of the global growing need for metals by 2040. Not even a hundred percent recycling rate will cover the volume of metals needed in the future.

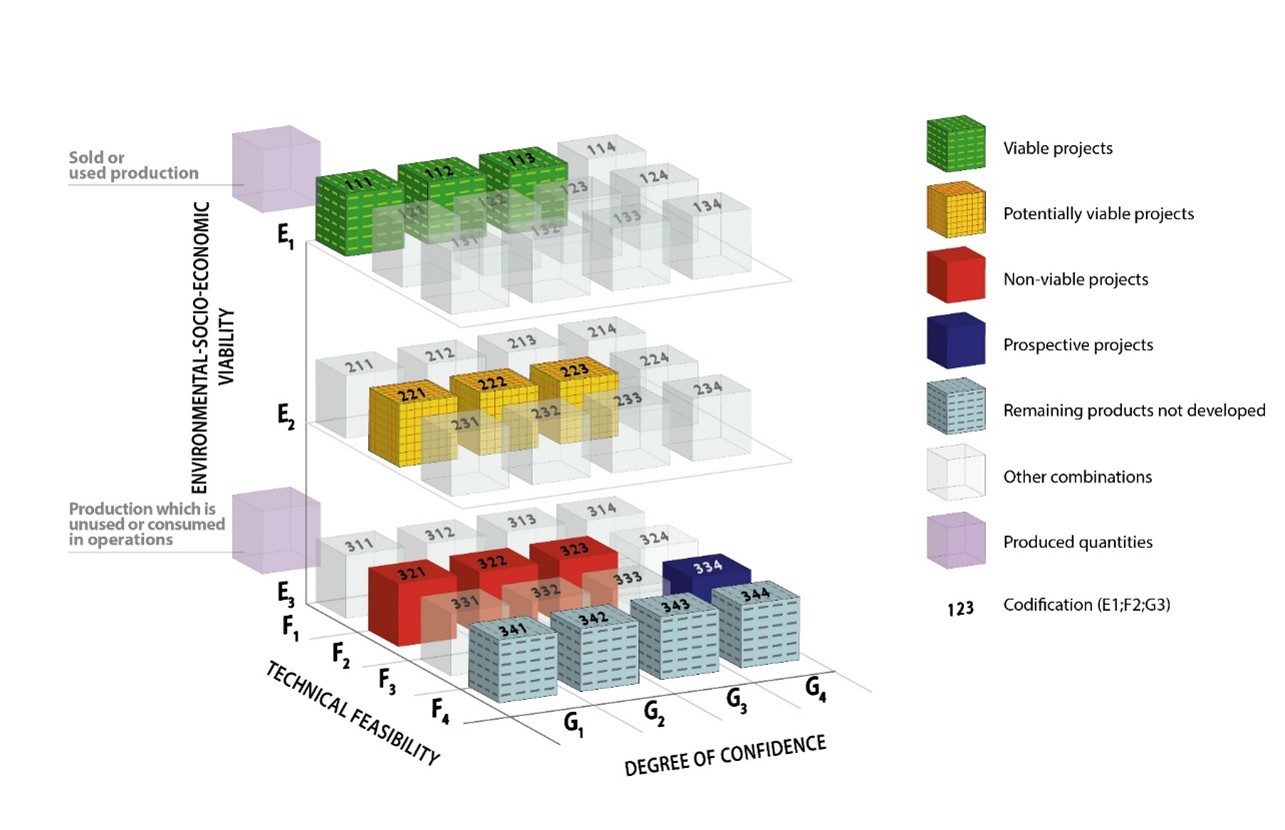

How much mineral resources and reserves are left, of what quality and where? The United Nations Framework Classification for Resources (UNFC) aims to answer these questions.

An overall picture from four sources

Mineral reserves are the part of a mineral deposit that can currently be extracted with profit, as the mining companies has determined in their feasibility studies. The rest of the known part of a deposit is classified as resources, mainly based on geological information. Volume of a resource indicates the potential for viable additional extraction over a specific timespan.

Information on the known quantities of raw materials is divided into four sources:

- Recyclable metals and minerals in infrastructure and products

- Metals and minerals in concentrates stored but not sold

- Primary and secondary resources and reserves yet to be mined or utilised

- Ore potential, i.e., possible mineral resources in mineral-potential geological environments

An understanding of a mineralised mass of rock for mining, processing, and metallurgy, for example, is needed to determine the mineral resources and reserves. In addition to these technical considerations, the economic feasibility of a deposit is affected by the related environmental, social, and economic framework.

Mineral resources and reserves are always based on estimates. Dilution is generated at every stage of the production chain, from the extraction of a rock containing a commodity to processing and final refining to a pure metal or mineral. All this also applies to secondary sources of raw materials, that is, the materials to be recycled, such as the mining waste.

Reliability of the knowledge of a resource increase in proportion to the acquired information. This means how accurately, with what “information density”, we have the data and information on the primary or secondary sources of raw materials. The information is obtained by surface investigations and drilling, as well as utilising geochemical and geophysical methods.

With different calculation methods, we can produce forecasts of the sufficiency of raw materials, based on the estimated needs of society. However, this does not tell us how much usable minerals and metals are left in the earth’s crust.

Research increases reserves

Long-term research and exploration increase mineral resources and reserves, be they from primary or secondary sources. A good example is the Swedish LKAB’s recent announcement about the vast phosphorus and REE (Rare Earth Elements) resources of the Per Geijer iron ore deposit near Kiruna in north of Sweden, which are, according to current knowledge, the largest REE resources in the EU (but not in Europe). The Per Geijer iron ores at Kiruna, N Sweden, were discovered more than 100 years ago, but only now we know how much there also is phosphate and REE.

It will take years until the by-products of Per Geijer deposit can be put into production. In any case, the estimated 0.9 million tonnes of rare earth metals would significantly help reduce Europe’s dependence on raw materials produced in China. There are probably much larger REE reserves in Sokli in Finland, but their quantity is not yet known.

The possibility of the economic utilisation of mining waste – waste rock and tailings – is increasing. It is hoped that the mines will translate more into circular economy ecosystems.

It must be remembered that the question is not only of making the extraction processes more efficient, as the quantity and quality of waste streams from different mines varies considerably. Today, the business benefit from recycling may still be relatively small, but EU and national legislations may oblige operators to process more of the waste in the future. This in turn will encourage the development of new business concepts.

A change is inevitable when moving over to a low-carbon society. Geosciences and material sciences play a critical role, and education in these fields will become even more important and would need more investment in worldwide. For some reason, the local and global trends seem to be the opposite, which is very worrying.

Critical materials at the core of the security of supply

Critical raw materials are at the core of the security of supply in the European Union. They are materials that are of key importance to the EU’s industry and subject to major availability risks.

The security of supply of mineral raw materials in Europe is taken care of by enabling long-term mineral research, making mining possible, and by maintaining and updating the vertical industrial integration, i.e., production chains from mining through processing into manufacturing in Europe. This by no means suggests that ore extraction will only take place within the European borders in the future. Various trade relations with countries belonging to the community of values in other continents are becoming even more important than they have so far been.

The focus is on understanding the production chains of mineral raw materials now and in the future. European-wide intellectual capital on raw materials and the harmonisation of classification of mineral resources are the cornerstones for the security of supply of raw materials in the European Union.

There is a growing need in the EU for sustainable and integrated raw material management that promotes the implementation of the green transition. The classification practices currently employed by the European Union’s Members States on mineral raw materials vary greatly, however.

Many countries are using a national standard, according to which country-specific mineral information is classified. However, this is not necessarily similar nor comparable even with the standard of a neighbouring country.

There are also Member States where no mandatory or even recommended classification practice is defined in the legislation. This needs to be changed. The Critical Raw Materials Act, which is currently being prepared in the European Commission, aims to address this and other questions.

Classification in three dimensions

UNFC is a global standard of sustainable management of natural resources, such as primary and secondary mineral resoruces, petroleum, renewable energy, geologic storage of CO2, and groundwater.

The placement of raw material mass in a UNFC class refers to the situation when the assessment was last made. For example, “Non-viable projects” means raw materials quantities the production of which was not economically viable at that time.

The UNFC system’s E-axis consists of environmental and socioeconomic variables that guide operators. These factors include political decisions, permits, taxes, royalties, and the social licence to operate.

Government agencies can also utilise the same variables by examining various dependencies and scaling from the project level to the national level. This enables more efficient and sustainable management of raw materials.

Pressure on raw material resources is created by strongly growing industries such as carbon capture, new means of transport, clean water, IT technologies, changes in the manufacturing industry, and the technology required by growing recycling.

Sustainable production and processing of raw materials with as little environmental burden as possible must, therefore, be quickly rendered to work efficiently and reliably, whether in mine production or recycling. A quick schedule means about 10–20 years, depending on what data and information is available and how quickly governments take action. The UNFC classification of resources is a practical tool in this work, as only with it all information in national and EU-wide resource accounting can be presented in a comprehensive, consistent, and harmonised way.

Text

Janne Hokka, Senior Specialist

Mineral Economy Solutions, Geological Survey of Finland GTK

Pasi Eilu, Senior Scientist

Pasi Eilu, Senior Scientist

Mineral Economy Solutions, Geological Survey of Finland GTK

The article was originally published in Finnish on MustRead Academy’s online service on January 24, 2023.

Geological Survey of Finland: Solutions to accelerate the transition to a sustainable, carbon-neutral world

The Geological Survey of Finland (GTK) produces impartial and objective research data and services in support of decision-making in industry, academia, and wider society to accelerate the transition to a sustainable, carbon-neutral world. GTK employs more than 400 experts specializing in the mineral economy, circular economy, solutions related to energy, water and the environment, as well as digital solutions. GTK is a research institution governed by the Finnish Ministry of Employment and the Economy, operating in Finland and globally.