New automation system at GTK Mintec

GTK Mintec in Outokumpu is one of the most sophisticated mineral and Circular Economy research infrastructure and pilot-scale mineral processing plants in Europe.

The future goals of the Geological Survey of Finland (GTK) include upgrading and developing the GTK Mintec unit by creating a digital experimental factory complex serving Finnish and international research and business. GTK Mintec is in the process of transforming from a traditional pilot plant to a modern, world’s best-practice mineral processing research and development platform. These changes, along with a digitalization project, include replacing the existing automation control system with a new state-of-the-art system.

The automation control system is the heart of the pilot plant operation, according to the Chief of Pilot Plant at GTK Mintec, Arno Kirpala¹. For each test run, a process designed based on the laboratory tests is drawn in the system and the physical assembling and mobilization of the pilot process takes place in parallel. The connections between the control system and field equipment are created in the control system to operate the plant equipment fleet and to monitor different measuring instruments from the control room (Fig. 1).

Schneider Electric was selected as the supplier of the new automation system. Schneider Electric is a global, growing technology company providing energy and automation digital solutions for efficiency and sustainability for customers. With aim of improving process visibility and reducing the project execution time in course with Pilot Plant operations, the new automation system EcoStruxure Process Expert was installed at GTK Mintec in December 2020.

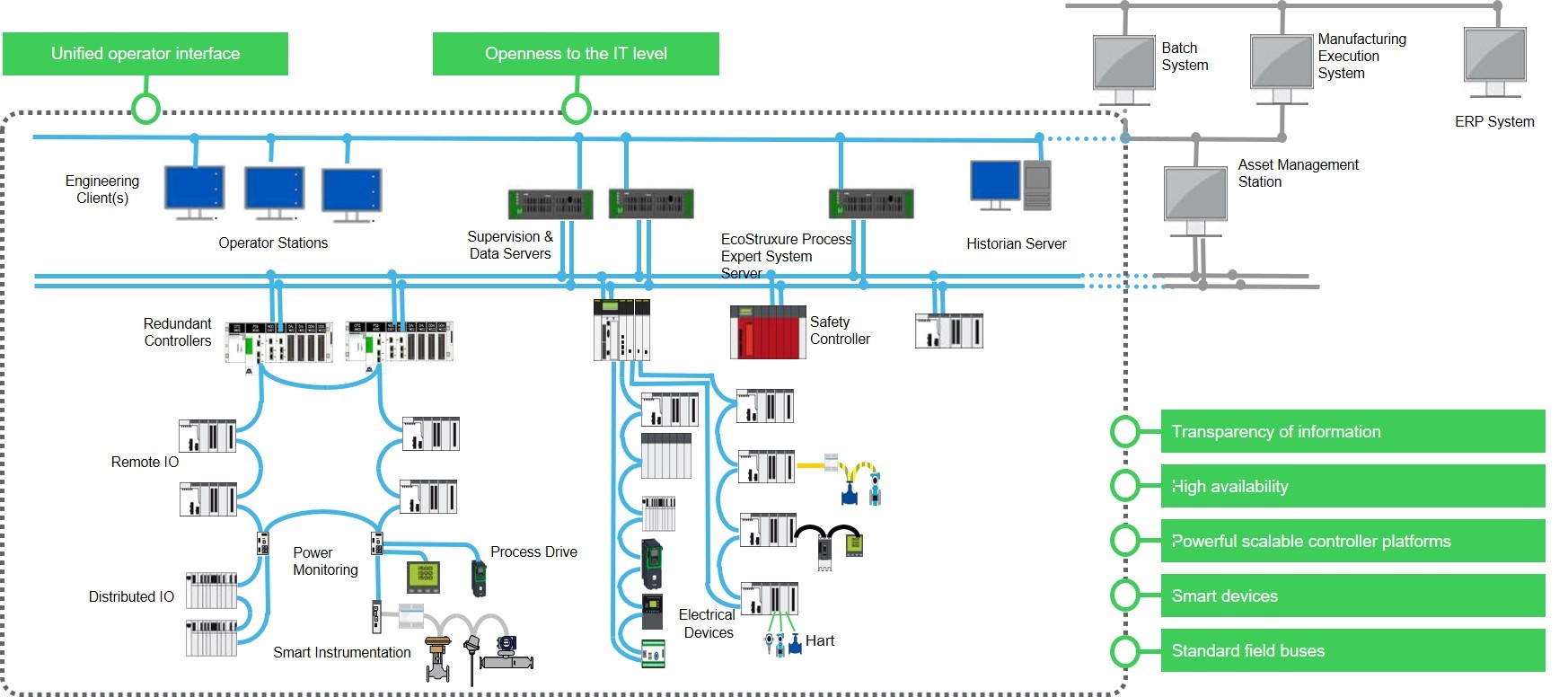

EcoStruxure Process Expert is an automation system, which allows users to engineer, operate and maintain an entire plant in a single common database. The system enables users to achieve operational profitability from design engineering to meeting the demands of modern day production. EcoStruxure Process Expert combines the management of fieldbuses, instrumentation, intelligent connected devices, operator stations, engineering stations and alarm management in a scalable, powerful automation platform.

EcoStruxure Process Expert is built on an Ethernet backbone for an open and flexible architecture. Ethernet topology offers transparent access to the information needed from the plant floor to the enterprise level. The system can interface with automation devices such as drives, motors starters as well as power management devices such as breakers and power meters. This enables EcoStruxure Process Expert to get accurate, real-time process data at any time. It helps measure, analyze and improve energy consumption and the overall operational profitability of the process with less waste, effort and cost. The connection of the new system was carried out by Pasram Oy company.

Figure 3: The control room (on the left) and server (on the right) at GTK Mintec. Image: GTK.

Hodouin highlighted, that “success in automation application relies not only on tools, but also on a deep knowledge of the phenomena involved in mineral processing, and on well-trained workers and engineers familiar with these new techniques – certainly the two weakest links in the control chain – and finally on a spirit of enthusiasm nurtured among engineering teams”. In order to familiarize GTK Mintec staff with the new automation system, a two-day Process Expert Training was organized in January 2021.

This new system will be integrated with several new instrumentation systems and new process units. State-of-the-art flotation cells have also been procured. The process system will be able to use the new kinds of data coming from these new cells.

The new process control system will allow GTK Mintec staff to operate in a manner that results in more effective recovery pilot runs. Once this system has been fully commissioned, each and every other part of the pilot plant process system will in turn be developed further.

More information

Schneider Electric Press Release

Outokumpu mineral processing pilot plant and laboratories – GTK Mintec

References

¹Digital Twin of the GTK Mintec Pilot Plant – For Customers and for Us

²Hodouin D., 2011: Methods for automatic control, observation, and optimization in mineral processing plants. Journal of Process Control, 21 pp. 211-225

Writers

Alona Nad, Postdoctoral Researcher, Mineral Processing and Materials Research, Circular Economy Solutions, Geological Survey of Finland (GTK), alona.nad@gtk.fi

Sanna Olkkonen, Channel Marketing Manager, Strategy and Development, Europe Operations, Schneider Electric, sanna.olkkonen@se.com

[…] https://www.gtk.fi/en/new-automation-system-at-gtk-mintec/ […]