How to Avoid the Commercial Leap to the Unknown When Utilising Anthropogenic Resources in Mining Sector?

Old mine waste sites are attracting interest as potential eco-friendly sources of secondary resources. Remining readily available mine wastes has advantages, but it is still challenging to make it profitably. GTK has developed expertise in estimating these secondary resources, which increases the utilization potential. This blog is shedding light to the matter from resource modelling and QA/QC perspective.

The concept of mining of anthropogenic resources (“remining”) or ‘secondary raw materials’ has long been considered as eco-friendly solution for the growing need of critical raw materials in Europe. Potentially, historical mine waste sites, including e.g., tailings facilities, waste rock piles, and water treatment sludges, contain valuable commodities which were not detected by contemporary analytical methods or were considered to have no economic value during the life of mine.

This implies that old mine sites are a potential resource for several sought-after metals and minerals for modern high-tech applications. Currently, a major interest is in metals needed for the low carbon energy production, storage, transmission, and use.

New mining, efficient use of critical raw materials, and recycling are all needed to secure a sustainable supply of raw materials in Europe and support circular economy. However, commercial utilisation of secondary resources including mine tailings is still limited. Why is it so?

One reason is the relatively low profit margins as the energy-hungry treatment processes simply do not cover the production costs of the saleable product. A commercial solution is necessary to make the treatment process profitable for large bulk of low metal grade materials such as tailings. This, naturally, depends on the complexity of the required treatment process, as the value of the metals extracted must both cover the treatment costs and allow for volatility of the metal prices.

Remining has many advantages but there is no one-size-fits-all solution

Remining has many advantages over mining projects that extract primary raw materials: (1) investments are considerably lower as the material is already processed and surface mining can be carried out by conventional truck and shovel method, and (2) environmental impact footprint is considerably lower.

Remining has many advantages over mining projects that extract primary raw materials: (1) investments are considerably lower as the material is already processed and surface mining can be carried out by conventional truck and shovel method, and (2) environmental impact footprint is considerably lower.

The operator may utilise the same disturbed ground and minimize the need of new land areas, besides reconstructing the historical mine waste area according to modern environmental and safety standards.

The remining can be also designed so that process waste can be backfilled into earlier closed near-surface stopes, which has positive environmental effects and provide better structural strength on the mine site.

Additional benefit is that the extraction of metals results in significantly smaller amounts of unwanted substances in the waste, which could lower the final closure costs of the mine waste facility. The overall process may reach up to 80 % revalorisation of the old mining wastes.

Furthermore, the recovery of valuable elements from water treatment sludge could, if not cover all the costs, at least bring some income to finance the obligatory water treatment expenses. Nevertheless, mine waste is very different in respect to the potential in-situ value, therefore, one-size-fits-all approach is not appropriate, and assessments of project viability need always robust investigation and resource definition.

From Reconnaissance Sampling to Resource Estimation

The technical information on historical production activities should be carefully reviewed. The important information includes for example: (1) sources and mineralogy of the processed ore, (2) mill head-grades, (3) historic re-processing activities, (4), technical specifications of the mineral processing plant, together with (5) production rates and dates.

Reconnaissance sampling (e.g., hand-dug pits) at random locations from the deposit is recommended before commencing a more extensive work, to confirm the presence of valuable metal contents and for initial waste classification. Historical documentation together with lidar data and aerial photos should be utilised to provide information on location of discharge outlets as this dictates the grain size distribution patterns.

The following data collection phases, depending on the accessibility and water saturation, may include excavations or initial drilling to determine the thickness and perimeter of the tailings and to collect additional samples at various depths for chemical assaying and grain-size distribution assessment. Also, ground geophysical surveys (e.g., electrical resistivity tomography (ERT), gravity and magnetic methods) provide indirect evidence of the thickness of the tailings pond as well as give valuable information on the ferromagnetic/conductive material.

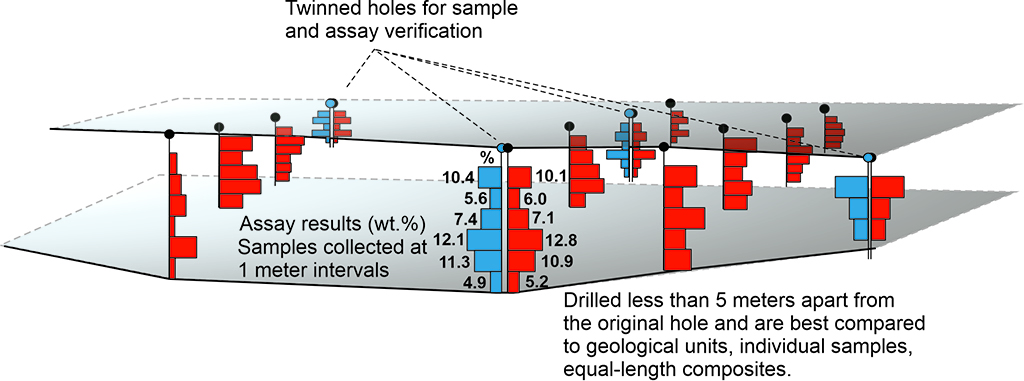

The quality of sampling needs to be assured as tailings typically are fine-grained sediment-water slurry, hence there is a major risk for contamination during sampling. To test the quality of drilling it can be done by drilling a twinned drillhole next to the original hole to produce a duplicate set of results which are then analysed and statistically quantified (Fig. 1). Other important aspects in quality control are the selection of correct sample preparation, analytical methods, and external quality-control samples for chemical assaying.

Especially, in Finland majority of tailings material are beneath the water table, thus, in saturated state. When estimating tailings resources one should also consider the accurate determination of dry bulk densities which are used to estimate the tonnage for tailings, with the volume estimation. The emphasis should be on representativeness of the samples and moisture content. A bulk density determination from loose material (“loose bulk density method”) can be calculated using a sample ring or box with a known volume and weight of the sample material.

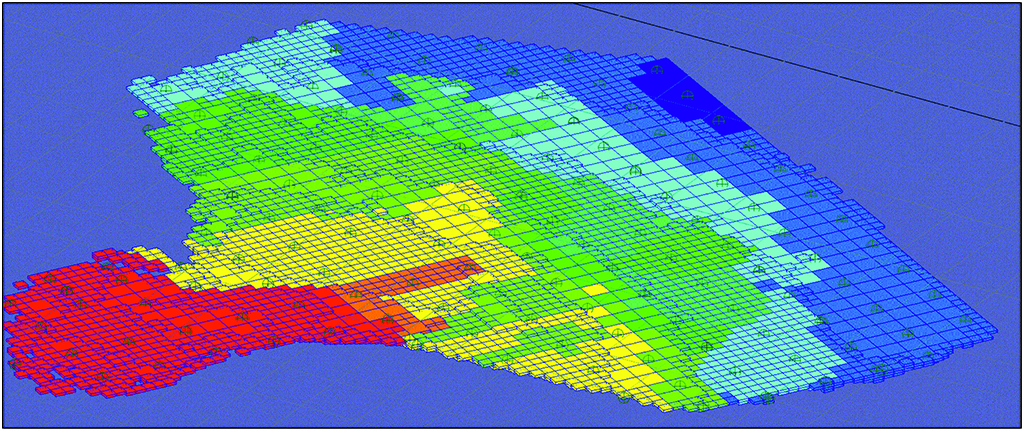

In respect to resource modelling, the process flow is similar to any other mineral resource estimates. The geological and grade continuity needs to be established, but also grain size distribution and continuation should be determined (Fig. 2). The accurate volume modelling needs topographic control, and thickness of tailings should be confirmed by drilling, not only based on indirect evidence. Modelling the edges of a tailings pond needs a more careful approach, and the boundary between the tailings and dam material should be determined.

The mineralogical characterisation and metallurgical tests should be planned and executed already in the reconnaissance phase. The material assessed may differ significantly from primary mined ore in respect to chemical and physical characteristics.

The preliminary metallurgical tests may well show that fine and coarse-grained material result similar concentrates but have a big difference in metal recovery. This may well mean that grade and particle size control methods are required, and to some extent selective mining may need consideration. Also, the option of stockpiling, material with different grade and grain size distribution, may become relevant in some cases to ensure the processing requirements and constant grade feed to the processing plant.

The challenges related to ground-water level and the possible effects of tailings material oxidation should also be understood. Estimation of unsaturated and saturated zones which affects gas diffusion and oxidation of sulphide minerals and, thus, affecting to mineral and drainage geochemistry. These changes can be studied for example by leaching tests.

GTK’s mineral and circular economy services provide clients with resource modelling, Quality Assurance, Quality Control (QA/QC) planning, and consulting and piloting in mining or recovering of secondary raw materials. These services are designed to provide clients with a reliable basis for assessing potential project value and assist in decision-making from data collection to mine closure.

If you wish to hear more, please contact Aleksi Salo aleksi.salo@gtk.fi or Teemu Karlsson teemu.karlsson@gtk.fi

Text

Janne Hokka, Senior Specialist (MSc – Geology, EurGeol), Geological Survey of Finland, janne.hokka@gtk.fi

Teemu Karlsson, Geologist (MSc – Geology, PhL – Applied Geochemistry, EurGeol), Geological Survey of Finland, teemu.karlsson@gtk.fi

Anna Tornivaara, Team Manager (MSc – Geology), Geological Survey of Finland, anna.tornivaara@gtk.fi

References

- Abzalov, M. Z., 2009. Use of Twinned Drillholes in Mineral Resource Estimation: Exploration and Mining Geology, v. 18, p. 13-23.

- Blengini, G.A., Mathieux, F., Mancini, L., Nyberg, M., Viegas, H.M., 2019, (Editors): Salminen, J., Garbarino, E., Orveillon, G., Saveyn, H., Mateos Aquilino, V., Llorens González, T., García Polonio, F., Horckmans, L., D’Hugues, P., Balomenos, E., Dino, G., de la Feld, M., Mádai, F., Földessy, J., Mucsi, G., Gombkötő, I., Calleja,I., Recovery of critical and other raw materials from mining waste and landfills: State of play on existing practices, EUR 29744 EN, Publications Office of the European Union, Luxembourg, doi:10.2760/600775, JRC116131.

- Markovaara-Koivisto, M., Valjus, T., Tarvainen, T., Huotari, T., Lerssi, J., Eklund, M., 2018. Preliminary volume and concentration estimation of the Aijala tailings pond – Evaluation of geophysical methods: Resource Policy, v. 59, p. 7-16, doi: https://doi.org/10.1016/j.resourpol.2018.08.016.